Mining Methodologies Through History

Early Mining Techniques

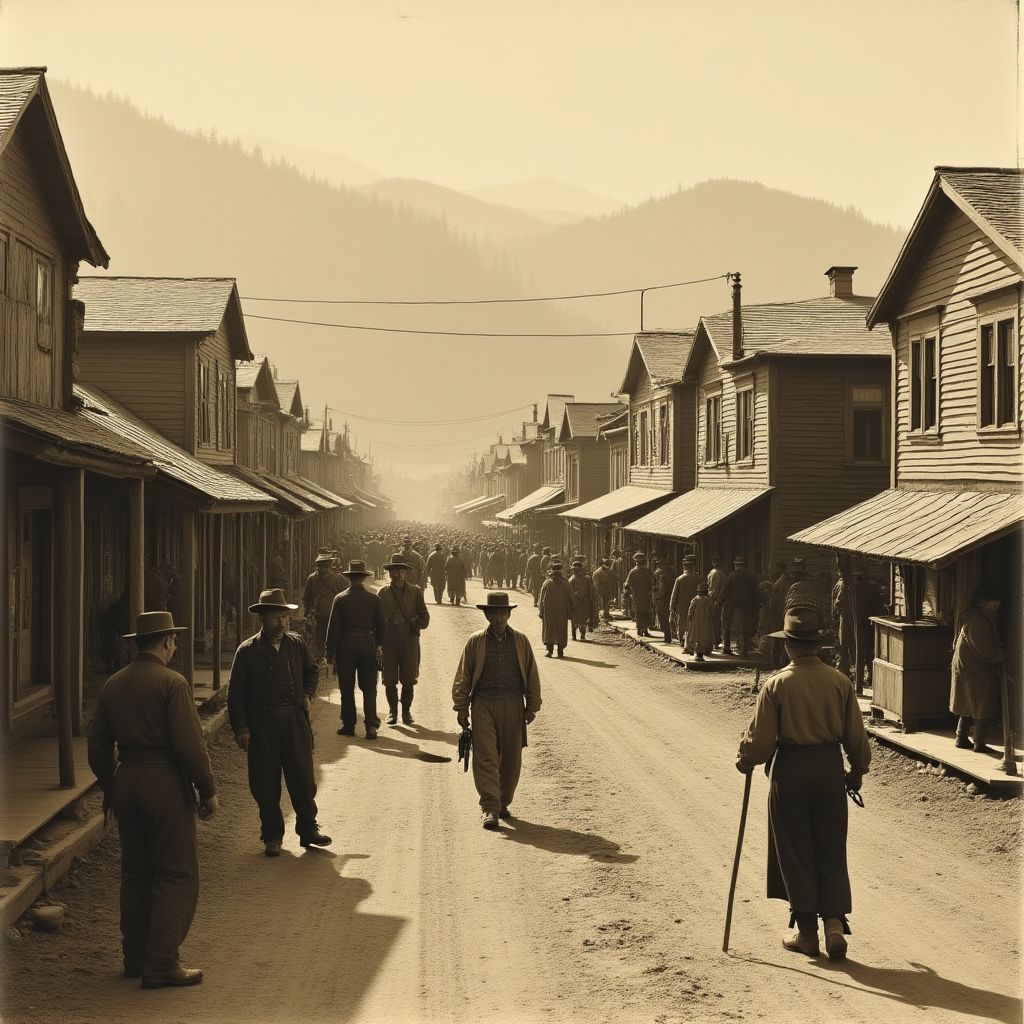

In the 1800s, mining was predominantly manual labor with basic tools like picks and shovels. Miners worked in hazardous conditions with minimal safety equipment, often leading to tragic accidents and health issues. Gold rushes around the world created boom towns where thousands flocked to seek their fortune. Coal mining expanded dramatically during this period to fuel the growing industrial revolution, while primitive extraction methods took a severe toll on both miners and the environment. Technological advances were limited, with steam-powered equipment just beginning to transform larger operations.

Industrial Revolution

The 20th century witnessed dramatic improvements in mining technology and safety standards. Mechanization transformed the industry with the introduction of pneumatic drills, conveyor belts, and later, hydraulic equipment that increased efficiency while reducing manual labor. Underground mining techniques became more sophisticated with better ventilation systems and structural supports. The mid-century saw the rise of uranium mining for nuclear energy and weapons programs, introducing new challenges and safety concerns. Labor movements gained strength, fighting for better wages and safer working conditions in mines worldwide. By the late century, environmental concerns began shaping mining practices as awareness of ecological impacts grew.

Modern Techniques

Contemporary mining employs cutting-edge technology including automated machinery, remote operation systems, and advanced geological modeling. Environmental rehabilitation has become a standard practice, with companies required to restore landscapes and mitigate ecological damage. Safety standards have improved dramatically with sophisticated monitoring systems, emergency protocols, and strict regulatory oversight. Large-scale operations now utilize massive equipment like draglines and hydraulic shovels that can move unprecedented amounts of material. The industry increasingly focuses on sustainability, reducing carbon footprints, and implementing renewable energy solutions at mining sites around the world.

Mining methodologies have evolved dramatically over centuries, transforming from basic manual techniques to sophisticated technological operations. Early miners relied on simple tools and brute strength, often working in extremely dangerous conditions with little understanding of geological principles or safety considerations. The industrial revolution brought steam power and mechanization, making extraction more efficient but still hazardous for workers.

The 20th century saw the development of industrial-scale mining with heavy machinery, improved ventilation systems, and the beginning of safety regulations. Modern mining operations employ cutting-edge technology including remote-controlled equipment, computer modeling, and environmentally conscious extraction methods. Today's miners benefit from extensive safety protocols, specialized training, and equipment designed to protect their health while maximizing productivity.